Bore drilling is a semi-closed cutting process, and the removal of chips as well as heat dissipation are challenging. With the development of industrial modernization, the demand for high-strength, high-wear resistance, large-diameter, and high-precision drilling processes is increasing. A high-performance drill becomes particularly important in meeting these requirements.

In terms of improving drill performance, the Chinese Multiface Drill dose well. This type of drill transforms the standard twist drill, known as “one point with three edges,” into “three points with seven edges.” It shows outstanding advantages in chip evacuation, drilling centering, quality, efficiency, and lifespan. Professor Hu commented, “Mr. Ni’s Chinese Multiface Drill is referred to as the 1.0. At that time, workers said that using this drill for bore processing is like Chinese tofu cutting, because drilling efficiency was improved noticeably.”

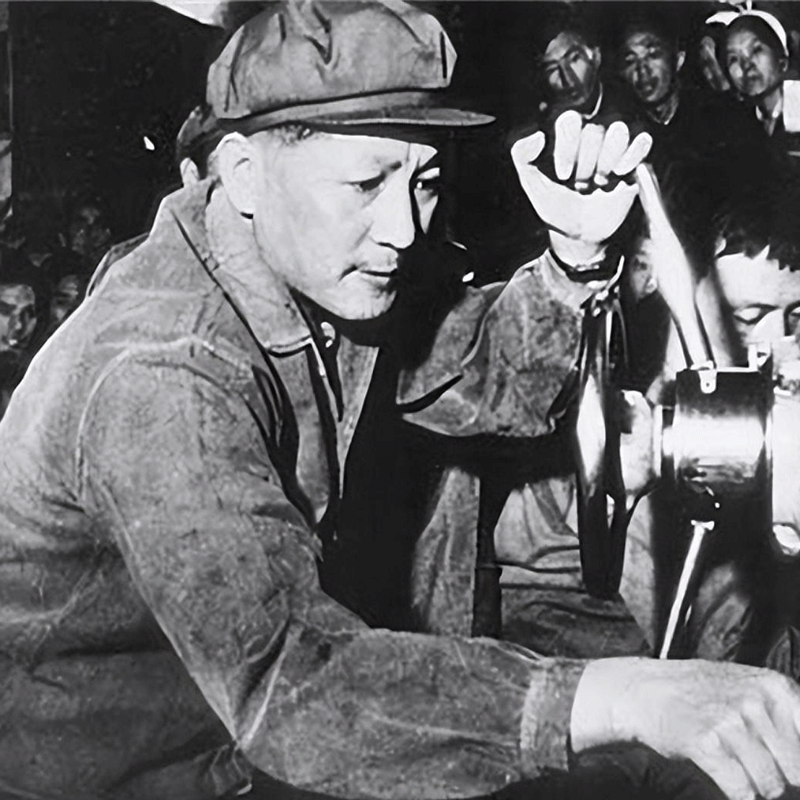

Historical Photo of Ni Zhifu

In 1953, the starting year of the “First Five-Year Plan,” it marked the beginning of the Chinese industrialization journey. Mr. Ni Zhifu, facing humble conditions, showcased the admirable qualities of workers by inventing Chinese Multiface drill amidst challenges, becoming a spiritual symbol of craftsmen in China. Professor Hu, recalling the visit of Mr. Ni to Hunan University, praised the older generation of craftsmen for their diligent thinking and courage to cope with changes, considering them as models.

Despite its outstanding performance, the drill faced challenges of high processing costs due to its reliance on manual grinding, making widespread application difficult. Subsequently, in the era of Chinese Multiface Drill 2.0 with simple mechanical fixture processing, the cost issue remained unresolved. Starting from the 1980s, the era of Chinese Multiface Drill 3.0 set sail. Hunan University’s research team solved the mathematical model of drill tips through solving partial differential equations, obtained corresponding grinding parameters, and achieved precise CNC processing of Chinese Multiface Drills through the developed five-axis CNC grinding machine. Since then, the design parameters of drill tips have met high-precision requirements, finally enabling manufacture. This achievement won the Mechanical Industry Science and Technology Progress Award and the Science and Technology Progress Award of Hunan Province in 2004 and received coverage from many well-known media outlets.